To start from where it ends……

"Embracing a sustainable future, RAS leads the way in recycling post-consumer materials, reminding us: 'Reuse your past, recycle your present to save your future.'"

Step 1 - Separating

We begin by feeding plastics-rich shredder residue into the process for size reduction. Next, we meticulously remove non-plastic materials such as metal, rubber, wood, glass, fluff, foam, textiles, and dirt.

Step 2 - Cleaning

In the washing and preparation stage, we eliminate non-target plastics. Our polyolefin purification process effectively cleans and sorts polypropylene (PP) and polyethylene (PE) polymers, while our styrenics purification targets and separates ABS and HIPS polymers.

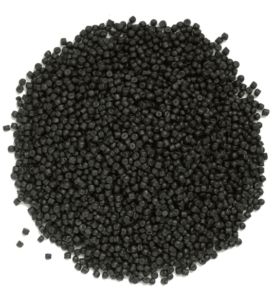

Step 3 - Finishing

Once the waste is cleaned, we proceed to formulate, blend, and compound the granulates. Following thorough quality checks, certification, and packaging, our customers receive a clean and sustainable product.